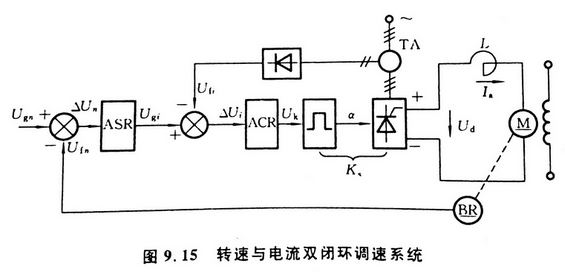

本次调速仿真采用PID调节。首先要确定PID中的各项设计参数,仿真过程中采用临界比例度法确定了大概的Kp值。在若干次调整的过程中,发现加入微分环节后调整时间略有上升,故采用PI调节。调整参数确定为Kp=75,Ki=22。控制器部分的程序如下图所示。原理图如下

ASR和ACR调节器均使用PI控制器,控制程序如下

代码如下:

type ElectricPotential = Real;

type ElectricCurrent = Real(quantity = "ElectricCurrent", unit = "A");

type Resistance = Real(quantity = "Resistance", unit = "Ohm", min = 0);

type Inductance = Real(quantity = "Inductance", unit = "H", min = 0);

type Voltage = ElectricPotential;

type Current = ElectricCurrent;

type Force = Real(quantity = "Force", unit = "N");

type Angle = Real(quantity = "Angle", unit = "rad", displayUnit = "deg");

type Torque = Real(quantity = "Torque", unit = "N.m");

type AngularVelocity = Real(quantity = "AngularVelocity", unit = "rad/s", displayUnit = "rev/min");

type AngularAcceleration = Real(quantity = "AngularAcceleration", unit = "rad/s2");

type MomentOfInertia = Real(quantity = "MomentOfInertia", unit = "kg.m2");

type Time = Real (final quantity="Time", final unit="s");

connector RotFlange_a "1D rotational flange (filled square)"

Angle phi "Absolute rotational angle of flange";

flow Torque tau "Torque in the flange";

end RotFlange_a; //From Modelica.Mechanical.Rotational.Interfaces

connector RotFlange_b "1D rotational flange (filled square)"

Angle phi "Absolute rotational angle of flange";

flow Torque tau "Torque in the flange";

end RotFlange_b; //From Modelica.Mechanical.Rotational.Interfaces

connector Pin "Pin of an electrical component"

Voltage v "Potential at the pin";

flow Current i "Current flowing into the pin";

end Pin; //From Modelica.Electrical.Analog.Interfaces

connector PositivePin "Positive pin of an electrical component"

Voltage v "Potential at the pin";

flow Current i "Current flowing into the pin";

end PositivePin; //From Modelica.Electrical.Analog.Interfaces

connector NegativePin "Negative pin of an electrical component"

Voltage v "Potential at the pin";

flow Current i "Current flowing into the pin";

end NegativePin; //From Modelica.Electrical.Analog.Interfaces

connector InPort "Connector with input signals of type Real"

parameter Integer n = 1 "Dimension of signal vector";

input Real signal[n] "Real input signals";

end InPort; // From Modelica.Blocks.Interfaces

connector OutPort "Connector with output signals of type Real"

parameter Integer n = 1 "Dimension of signal vector";

output Real signal[n] "Real output signals";

end OutPort; // From Modelica.Blocks.Interfaces

partial model Rigid // Rotational class Rigid

"Base class for the rigid connection of two rotational 1D flanges"

Angle phi "Absolute rotation angle of component";

RotFlange_a rotFlange_a "(left) driving flange (axis directed into plane)";

RotFlange_b rotFlange_b "(right) driven flange (axis directed out of plane)";

equation

rotFlange_a.phi = phi;

rotFlange_b.phi = phi;

end Rigid; // From Modelica.Mechanics.Rotational.Interfaces

model Inertia "1D rotational component with inertia"

extends Rigid;

parameter MomentOfInertia J = 1 "Moment of inertia";

AngularVelocity w "Absolute angular velocity of component";

AngularAcceleration a "Absolute angular acceleration of component";

equation

w = der(phi);

a = der(w);

J*a = rotFlange_a.tau + rotFlange_b.tau;

end Inertia; //From Modelica.Mechanics.Rotational

partial model TwoPin // Same as OnePort in Modelica.Electrical.Analog.Interfaces

"Component with two electrical pins p and n and current i from p to n"

Voltage v "Voltage drop between the two pins (= p.v - n.v)";

Current i "Current flowing from pin p to pin n";

PositivePin p;

NegativePin n;

equation

v = p.v - n.v;

0 = p.i + n.i;

i = p.i;

end TwoPin;

model DCMotor "DC Motor"

extends TwoPin;

extends Rigid;

OutPort SensorVelocity(n=1);

OutPort SensorCurrent(n=1);

parameter MomentOfInertia J"Total Inertia";

parameter Resistance R"Armature Resistance";

parameter Inductance L"Armature Inductance";

parameter Real Kt"Torque Constant";

parameter Real Ke"EMF Constant";

AngularVelocity w "Angular velocity of motor";

AngularAcceleration a "Absolute angular acceleration of motor";

Torque tau_motor;

RotFlange_b rotFlange_b; // Rotational Flange_b

equation

w = der(rotFlange_b.phi);

a = der(w);

v = R*i+Ke*w+L*der(i);

tau_motor = Kt*i;

J*a = tau_motor + rotFlange_b.tau;

SensorVelocity.signal[1] = w;

SensorCurrent.signal[1] =i;

end DCMotor;

class Resistor "Ideal linear electrical Resistor"

extends TwoPin; // Same as OnePort

parameter Real R(unit = "Ohm") "Resistance";

equation

R*i = v;

end Resistor; // From Modelica.Electrical.Analog.Basic

class Inductor "Ideal linear electrical Inductor"

extends TwoPin; // Same as OnePort

parameter Real L(unit = "H") "Inductance";

equation

v = L*der(i);

end Inductor; // From Modelica.Electrical.Analog.Basic

class Ground "Ground node"

Pin p;

equation

p.v = 0;

end Ground; // From Modelica.Electrical.Analog.Basic

model PWMVoltageSource

extends TwoPin;

InPort Command(n=1);

parameter Time T = 0.003;

parameter Voltage Vin = 200;

equation

T*der(v)+ v = Vin*Command.signal[1]/10;

end PWMVoltageSource;

block Controller

InPort command(n=1);

InPort feedback(n=1);

OutPort outPort(n=1);

Real error;

Real pout;

Real intU;

parameter Real Kp=70;

parameter Real Ki=20;

equation

error = command.signal[1] - feedback.signal[1];

error =der(intU);

pout = Kp * error+Ki*intU;

outPort.signal[1] = pout;

end Controller;

block CommandSignalGenerator

OutPort outPort(n=1);

Real acc;

equation

if time <= 1 then

acc =60;

elseif time <3 then

acc = 0;

elseif time <4 then

acc = -60;

else

acc = 0;

end if;

der(outPort.signal[1]) = acc;

end CommandSignalGenerator;

model DCMotorControlSystem

Ground ground1;

Inertia inertia1(J = 3, w(fixed = true));

DCMotor motor1(J = 1,R = 0.6,L = 0.01,Kt=1.8, Ke=1.8,rotFlange_b(phi(fixed = true)));

CommandSignalGenerator sg1;

Controller con1;

Controller con2;

PWMVoltageSource PowerSource1;

equation

connect(sg1.outPort, con1.command);

connect(con1.feedback, motor1.SensorVelocity);

connect(con1.outPort, con2.command);

connect(motor1.SensorCurrent,con2.feedback);

connect(con2.outPort, PowerSource1.Command);

connect(PowerSource1.p, motor1.p);

connect(motor1.rotFlange_b, inertia1.rotFlange_a);

connect(PowerSource1.n, ground1.p);

connect(ground1.p, motor1.n);

end DCMotorControlSystem;

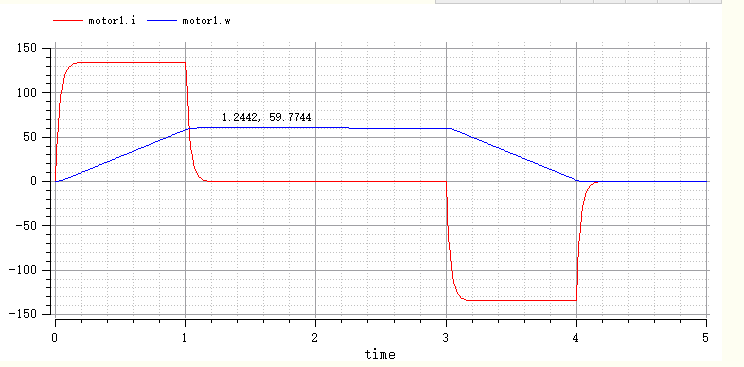

调节出的曲线